Steel is 1080 Scales are Mahogany

As with other stock removal knives of mine, the profile was marked out with a maker. The basic shape was uncomplicated and that of a typical hunting knife.

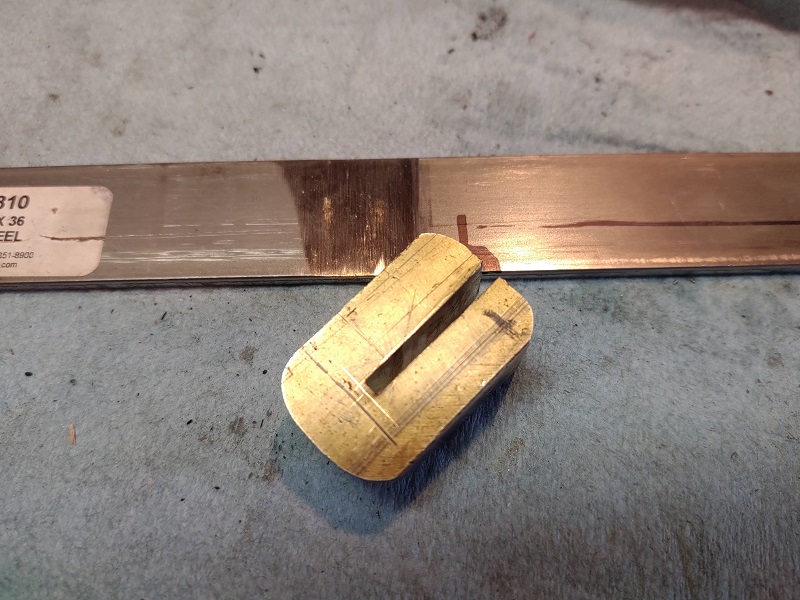

The U shaped brass finger guard was fitted buy cutting the slot, then slowly filing it until it fit. The blade was also filed slightly to create a very shallow shoulder for the brass to slide up to. It was then drilled for 2 brass 1/8” rods which were peened on (after heat treating).

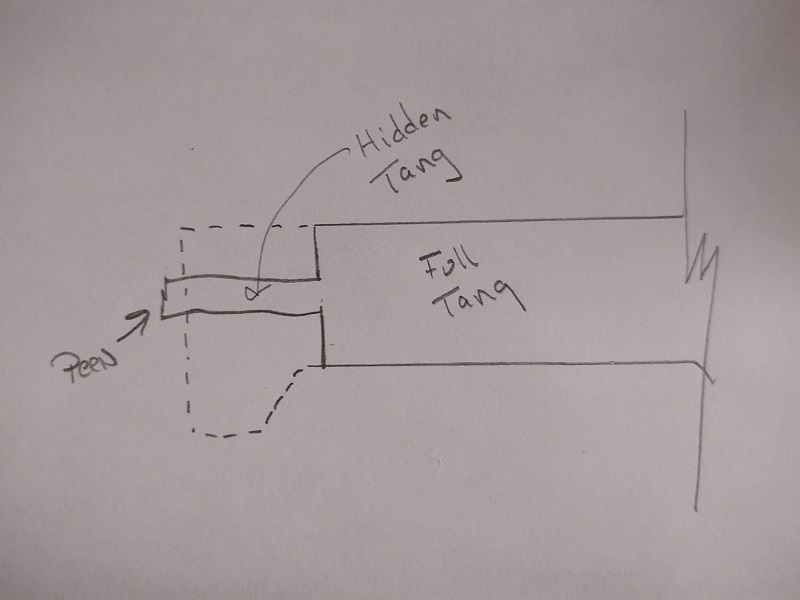

The cap was fitted in the same manner, but it was held in place by peening the tang.

Both the cap and finger guard were fitted prior to the bevel being ground.

I made a small mistake on the scales when I put it together. I didn’t make the scales flush with the top of the cut out for the cap. My thought was peeing would tighten the whole thing. What I didn’t anticipate was the small gap. It’s not a terrible gap, but I know it’s there.

So, the lesson learned is dry fit your design and inspect it very carefully. I should have caught the mistake, but I did not.

Although not completely necessary, i slightly taper the holes from each side to help the peening action hold the guard in place.

________________

As an Amazon associate, we earn income from qualifying purchases when you click on a link. Your link clicks help us fund our website.________________